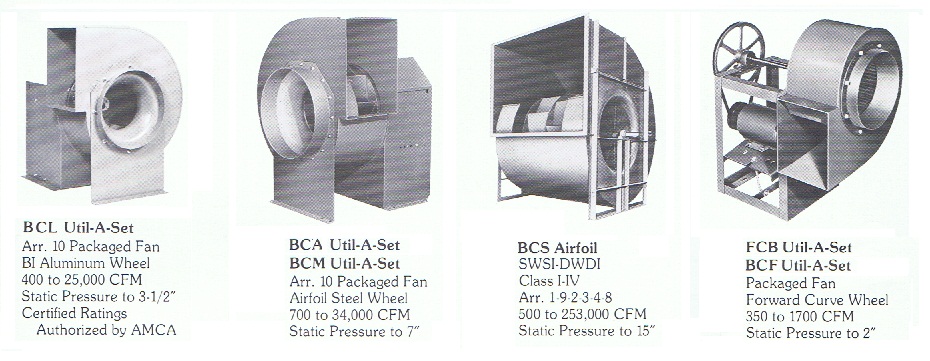

Industrial Centrifugal Fans

Canada Blower industrial

radial blowers

RBO, RD, BP, LS, XO, DH, RTS, Radial Tip fans: industrial radial

blade blowers are supplied in welded heavy gauge steel construction to

prevent flexing at high pressure. Available in direct drive

arrangements 4/4V/4H/7/8 and belt drive arrangements 1/3/9/10. Arr. 10

blowers are known as ventilating sets (Canada Blower vent sets).

Available in single width single inlet (SWSI), or double width double

inlet (DWDI). Capacities: to 500,000 CFM. Static pressure up to 100

inches water gauge depending on the class of construction. Typical

class of construction is Class 1, 2, 3, 4, 5.

Aluminum wheel, Steel wheel, or Alloy wheel: industrial radial blowers

and fans are supplied with aluminum wheel or corten wheel to meet

requirements of AMCA A, and AMCA B spark resistant construction. Mild

steel wheels are of all welded construction. They are used on pressure

applications, material handling applications (plastic scrap, paper

trim, granular material, low density bulk material) where Canada Blower

wheel is reinforced with support gussets, or made of abraision

resistant construction, or furnished of high strenght steel. Stainless

steel wheel in 304 SS, 316 SS, 316 SS, 2205 SS are supplied for

corrosive applications, or high temeparature applications. The pressure

curve remains stable from fully open to fully closed position.

Industrial Blowers are

designed to handle industrial process air. Fan features a radial design

fan wheel, available as air-handling AH wheel, or material handling MH

wheel. Fan construction features rigid housing, braced for additional

strenght, heavy duty shaft, heavy duty pillow block bearings, shaft and

bearing pedestal, adjustable motor

base, and weather motor cover. Flanged Inlet / Outlet, Companion

flanges, Access Door, Drain, Plug, Damper, Spark Resistant

Construction, Abrasion Resistant

Construction, High Temperature Fan Construction to 800 F, and vibration

insulation

are optional. Special alloys and coatings are avaialble upon request.

Pressure Blowers and Turbo Pressure Blowers are general industrial fans designed to handle industrial process air at high pressure. Fan features pressure blower all welded steel radial wheel, which on junior pressure blowers is of cast aluminum design. Fan construction includes heavy duty rigid housing, which on junior fans is of cast iron blower design, reinforced with braces, blower wheel, heavy duty shaft, heavy duty pillow block bearings, shaft and bearing pedestal, adjustable motor base, and weather motor cover. Flanged Inlet, Flanged Outlet, Companion flanges, Access Door, Drain, Plug, Inlet Screen, Outlet Guard, Dampers, Spark Resistant Construction, Abrasion Resistant Construction, High Temperature Blower Construction to 800 F, and vibration insulation are optional accessories. Direct drive fans are avialble in Arr. 8 construction. Belt drive fan arrangements utilize standard V-belt drive supplied in fixed pitch, or adjustable pitch option. Special alloys and coatings are avaialble upon request.

Plug Fans are designed to handle industrial process air for air recirculation in ovens and furnaces. Fan features inlet cone with venturi profile, a non-overloading backward inclined, backward curved, or airfoil wheel, heavy duty shaft and bearings, shaft and bearings pedestal reinforced with braces, adjustable motor base, and belt guard. Spark Resistant Ventilator Construction, Abrasion Resistant Fan Construction, High Temperature Construction to 1500 F, are optional accessories. Direct drive fans are avialble in Arr. 4 construction. Belt drive arrangements utilize standard V-belt drive supplied in fixed pitch, or adjustable fan pitch option. Special alloys and coatings are avaialble upon request.

Fan accessories: Prefabricated unitary base, safety bird screen, shaft and bearing guard, belt guard, weather and motor cover, automatic and Motor-Operated Backdraft Dampers, inlet vane dampers, flanged inlet, flanged outlet, access door, drain and plug, spring or rubber vibration isolators, and high temperature construction are avaialble upon request. Special protective coatings and alloys (aluminum, or stainless) are optional. Pre-wired and loose Safety Disconnect Switch, and Speed Controller are optional.

All models power roof

ventilators bear the AMCA Seal.

Call us today: 1-888-763-1800 E-mail: nis@primus.ca